During the virtual 2021 Southern Student Regional Conference hosted by the University of Louisville this March, this year’s USF American Institute of Chemical Engineers (AIChE) student team placed 6th in the conference’s Chem-E-Car Competition and placed 1st in the competition’s poster presentation section.

USF AIChE Chem-E-Car Competition chairs Joel James and Steven Collins said that this year’s poster was the student organization’s best in its consecutive ten-year history of the competition and that the team’s performance was its best in its last three years and put it one spot shy of advancing to this year’s Chem-E-Car nationals.

“We recorded a five-minute presentation of our poster, which we submitted to the judges, and then before the day of the competition there was a separate Q&A session where they asked us a lot of questions about the poster,” Collins said. “It wasn’t until after the competition that we learned we won the poster portion, which was a pleasant surprise.”

The competition challenges student AIChE chapters in regions around the U.S. to spend a year designing and constructing a small, chemically-powered car capable of automatically travelling a specified distance between 15-30 meters before stopping. Chapter teams that win first and second place in their regional competition are awarded $200 and $100 respectively, as well as a spot in the national Chem-E-Car Competition Finals and a chance to win up to $2,000 plus the prestigious Chem-E-Car Competition Award.

Perhaps the most valuable reward of the competition, however, is the unique experience participating students gain from working on a team to build a robotic car powered solely by chemical reactions.

“We try to accommodate as many people as possible,” Collins said. “Our main priority is giving USF students experience learning engineering skills outside their disciplines they might not learn in their major.”

This year’s team was organized in a hierarchy of engineering students who signed up with USF AIChE. Any USF student could apply to work on the team car, but those looking to lead the design of the car’s chassis, power supply, stopping mechanism or electrical configuration go through a more rigorous interview process earlier in the year to evaluate their engineering design experience and capabilities.

As team chairs, James and Collins set project deadlines, ran weekly meetings, and delegated tasks to team members. In addition to managing the construction of the team car, they also led the necessary lab experiments for designing the car and assisted in completing the car’s four main components — its chassis, battery, electrical system and stopping mechanism. James had a more hands-on role in optimizing most of these functions, while Collins focused on task management, team recruitment, competition compliance and planning and advertising team meetings.

James and Collins also helped train team leads in running necessary lab experiments on their own for their respective tasks and team members. One to three students worked under each of the four team leads, for a total of 13 Chem-E-Car team members.

Collins said that one of the biggest challenges this year was the unusual time constraint the team was under. The designs of the three previous USF AIChE Chem-E-Car teams didn’t make it past the starting line, forcing team leads this year to start from scratch instead of being able to modify earlier component setups and focus more on construction. He said that it’s common for many teams’ cars to not move at all during both rounds of the competition due to their designs performing differently in the field than in the lab.

While teams typically get a year to prepare for the Chem-E-Car Competition, the 2020 competition was delayed from March 2020 to November 2020. The 2021 competition was still slated to take place again in March, however. James said this gave their team four months to design and build their car nearly from the ground up. He said this also gave him less time to help train team leads, as some hadn’t competed in a Chem-E-Car Competition before and had just began their major engineering course work in their programs.

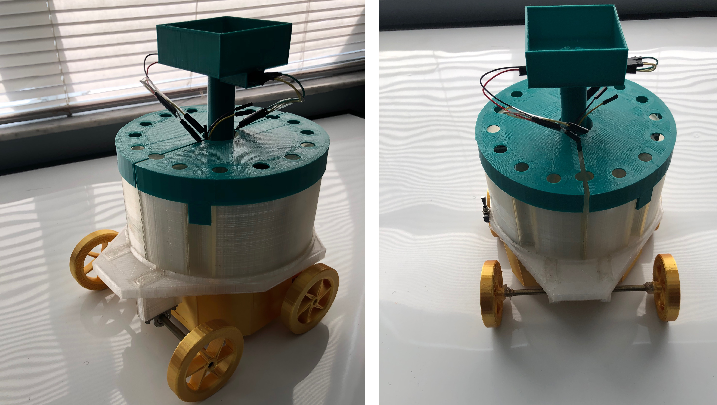

Despite these hurdles, Collins and James said team members’ dedication to the project and reliability allowed them to finish the car on time before their final deadline. This included a green and gold 3D-printed chassis made with a 3D printer James owns. He said that the time spent re-printing and editing parts paid off in the poster competition, as a unique design was one of the judging criteria, and the stylized look of the car likely gave the team an advantage.

“A lot of the cars that we see at the competition are usually made of square aluminum plates shaped into boxes,” James said. “One of the ones we saw more recently used a metal base plate with Tupperware on top to house its reactions.”

The green and gold body of this year’s USF AIChE Chem-E-Car Competition entry was made of different 3D printed parts.

On the day of the virtual competition, the team set their car in a hallway on campus marked with painter’s tape to visualize the distance the car needed to travel without hitting either wall or straying out of bounds past the designated stop point and risk being penalized. Each team was given two trial runs, each two minutes long, to get the closest they could to their goal using only chemical reactions to power and stop providing power to their cars.

“You can have store-bought batteries to power your circuit, but they can’t be powering the motor that stops your car, and you cannot have mechanical brakes,” James said. “Until the day of the competition now, you don’t know the distance you’ll have to run but it’ll be between somewhere between 15 and 30 meters.”

The team chose its final set of reactions used to stop the car after performing many experiments in the lab to find a reliable solution for controlling how quickly it would come to a halt. The mechanism works by decomposing hydrogen peroxide, which releases oxygen gas that’s trapped by dish soap to form foam. This foam climbs up a column on the top of the car to gradually block a laser from hitting a sensor, signaling an Arduino in the car to open the car’s circuit, shut down the motor, and bring the car to a stop.

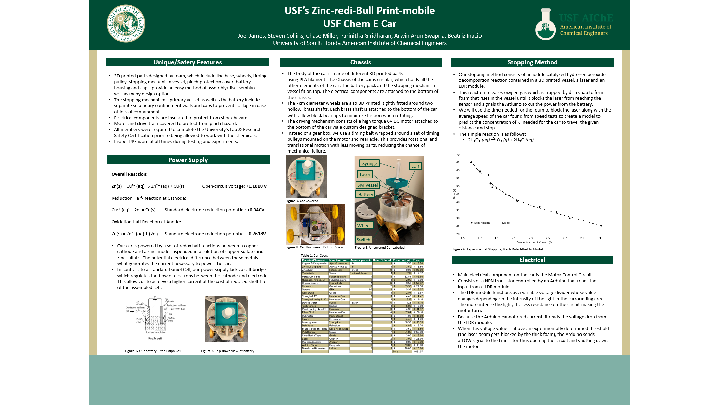

The USF AIChE Chem-E-Car team submitted this slide for the competition’s poster portion detailing its design and construction, as well as a five-minute video presentation. The team’s poster was based off formal research posters typically presented at research symposiums.

Learn more about the team’s award-winning Chem-E-Car Competition design and see the full list of car materials by downloading a copy of the USF AIChE team’s digital poster.